Call: 08071931936

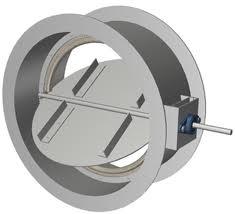

PNEUMATIC BUTTERFLY DAMPERS

Product Details:

- Usage & Applications Industrial ventilation, HVAC, Dust collection, Process gas line, Air handling units

- Installation Guideline Horizontally or vertically mounted; Full flange bolt connection

- Driven Type Pneumatic

- Accessories Position Indicator, Solenoid Valve, Limit Switch, Air Filter Regulator, Manual Override

- Automation Grade Automatic

- Production Capacity On Order / As Required

- Speed Quick Open/Close (as per actuator)

- Click to View more

X

PNEUMATIC BUTTERFLY DAMPERS Product Specifications

- Low (Pneumatic Driven)

- Mild Steel / Stainless Steel

- Industrial ventilation, HVAC, Dust collection, Process gas line, Air handling units

- Horizontally or vertically mounted; Full flange bolt connection

- Blue / Grey / Customized as per request

- Powder Coated / Painted / SS Polished

- Pneumatic

- Automatic

- Depends on actuator specifications

- Position Indicator, Solenoid Valve, Limit Switch, Air Filter Regulator, Manual Override

- Customizable as per application

- No

- Up to 95% sealing efficiency

- Pneumatic Actuator

- Pneumatically Actuated

- Pneumatic Butterfly Damper

- Varies as per size (15 200 kg)

- Industrial Air Flow Control Damper

- Quick Open/Close (as per actuator)

- Automatic

- On Order / As Required

- Upto 10000 Nm/hr (varies by size)

Product Description

With an aim to fulfill varied needs of different industrial applications, we are affianced in providing technologically advanced Pneumatic Butterfly Dampers. These dampers are manufactured using premium quality raw material with the aid of ultra-modern techniques. Our provided dampers are is best suitable to control the flow of water. Highly demanded in oil & gas, petrochemical, pharmaceutical and other allied industries, offered Pneumatic Butterfly Dampers are excellent in functionality which makes these widely demanded by our customers.

Features:

-

Hassle-free performance

-

High operational fluency

-

Anti-corrosive

-

Longer service life

Advanced Sealing Options

Choose between elastomer or metal-to-metal sealing types, ensuring optimal performance for various industrial conditions. Seat materials such as EPDM, Nitrile, Silicon, PTFE, or Metal provide customized solutions for chemical compatibility and durability. These options enhance sealing efficiency and minimize leakage, complying with API 598 Class III & IV requirements.

High-Quality Construction and Versatility

Dampers are available in multiple body types: wafer, lug, and flanged ends. The robust disk material choicesMild Steel, SS304, SS316, or Aluminiumensure long life and corrosion resistance. Designed for installation in HVAC, dust collection, process gas lines, and air handling units; suitable for both horizontal and vertical mounting.

Reliable Pneumatic Actuation

Equipped with double-acting or spring-return pneumatic actuators, these dampers operate on compressed air (57 bar) and offer quick open/close functionality. Control accessories such as position indicators, solenoid valves, limit switches, and air filter regulators further enhance automation and operational efficiency.

FAQs of PNEUMATIC BUTTERFLY DAMPERS:

Q: How do pneumatic butterfly dampers achieve efficient sealing?

A: Pneumatic butterfly dampers use either elastomer seats (such as EPDM, Nitrile, Silicon, PTFE) or metal-to-metal sealing, depending on the application needs. This ensures up to 95% sealing efficiency, meeting Class III & IV leakage standards as per API 598.Q: What is the recommended operating pressure and media for these dampers?

A: These dampers are suitable for pressures up to 5 bar and operate with compressed air (57 bar) as their actuating medium, ensuring consistent and reliable performance in industrial environments.Q: When should I choose double acting versus spring return actuator types?

A: Select double acting actuators for applications needing precise bidirectional control, while spring return types are ideal when automatic return to a default position after air supply loss is required, enhancing system safety.Q: Where are pneumatic butterfly dampers typically installed?

A: They are commonly installed in industrial ventilation systems, HVAC units, dust collection systems, process gas pipelines, and air handling units. Dampers can be mounted horizontally or vertically with full flange bolt connections.Q: What is the process for installing these dampers?

A: Install the damper using the specified end connection (flanged or wafer) and ensure full flange bolt connection for secure mounting. Detailed installation guidelines enable correct horizontal or vertical placement and integration with accessories like solenoid valves and limit switches.Q: How do these dampers benefit industrial air flow control systems?

A: With quick open/close actuation, high sealing efficiency, and durable construction, these dampers maximize energy efficiency, reduce air leakage, and help maintain precise environmental control within complex industry setups.Q: What packaging and sizes are available for export and large-scale applications?

A: Dampers are packaged in export-quality wooden boxes, accommodating port sizes from DN50 to DN1200 and above. Custom dimensions and colors are available on order to meet specific project requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry