Call: 08071931936

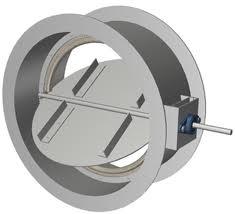

MANUAL BUBBLE TIGHT DAMPERS

Product Details:

- Automation Grade Manual

- Driven Type Manual Hand Lever / Wheel

- Accessories Position Indicator, Gaskets, Mounting Flanges

- Model No As specified by manufacturer

- Efficiency (%) 100% shutoff when closed

- Speed Manual Operation (No Motorized Speed)

- Usage & Applications HVAC, Power Plants, Industrial Ventilation, Process Industry, Clean Rooms

- Click to View more

X

MANUAL BUBBLE TIGHT DAMPERS Product Specifications

- Silver or customized

- Manufacturer / Supplier

- Flow control damper

- Up to 250C or customized

- No

- As per order

- Manual

- Galvanized Steel / Mild Steel / Stainless Steel

- As per client specification

- Manual Hand Lever / Wheel

- Manual

- Manual Operation (No Motorized Speed)

- 100% shutoff when closed

- As specified by manufacturer

- Position Indicator, Gaskets, Mounting Flanges

- Manual

- Nil

- Depends on Size & Material

- Customizable as per requirements

- Manual Bubble Tight Damper

- Bubble tight shutoff, robust construction, zero leakage, easy operation, corrosion resistance

- Lever or Hand Wheel Operation

- HVAC, Power Plants, Industrial Ventilation, Process Industry, Clean Rooms

- Powder Coated / Painted / Galvanized

Product Description

MANUAL BUBBLE TIGHT DAMPERS

We are the leading manufacturer, supplier and exporter of MANUAL BUBBLE TIGHT DAMPERS in India. We provide MANUAL BUBBLE TIGHT DAMPERS in order to fulfill the need of industries. We also supply the MANUAL BUBBLE TIGHT DAMPERS as per the need of clients. We provide these MANUAL BUBBLE TIGHT DAMPERS at much competitive rates in the market, Our product MANUAL BUBBLE TIGHT DAMPERS has good approach in the market and caters to the emerging needs of market.

- Pressure: 300-500 mm Aq

- Port Size: 5"-66"

Zero Leakage, Bubble Tight Sealing

Built to rigorous BS and ASME standards, these dampers feature a bubble tight design that ensures complete shutoff. This makes them perfect for any application where absolute sealing is mission-critical, delivering reliable performance under demanding conditions and preventing loss or contamination of airflow in critical environments.

Customizable and Durable Construction

Available in galvanized, mild, or stainless steel, Manual Bubble Tight Dampers offer a choice of finishes including powder coating, painting, or galvanization. Their robust build ensures longevity and resistance to corrosion, while the customizable dimensions and weight accommodate unique installation scenarios. Accessories like mounting flanges and position indicators add to operational convenience.

Efficient Manual Control and Long Service Life

Operated via lever or hand wheel, these dampers require minimal torque, making manual handling straightforward and efficient. With no need for external power, they provide dependable control in settings lacking automation. Each damper undergoes tight shutoff testing to guarantee over 20 years of service life under typical operations.

FAQs of MANUAL BUBBLE TIGHT DAMPERS:

Q: How does a Manual Bubble Tight Damper ensure zero leakage during operation?

A: The damper features a precision-engineered sealing system designed to provide a bubble tight shutoff. When closed, the blades make full contact with the gaskets, preventing any passage of air or gas, and testing is conducted in accordance with BS and ASME standards to confirm zero leakage capabilities.Q: What materials are used in manufacturing these dampers?

A: Manual Bubble Tight Dampers are fabricated from galvanized steel, mild steel, or stainless steel, depending on the clients requirements and application. These materials provide excellent durability and resistance to corrosion, enhancing the dampers longevity and reliability.Q: When should I consider using a manual bubble tight damper?

A: These dampers are ideal for installations where complete shutoff is vital, such as HVAC systems, industrial ventilation, clean rooms, power plants, and process industries. They are also suitable where manual operation and 100% efficiency are priorities and where automated control is unnecessary or unavailable.Q: Where can these dampers be installed?

A: Manual Bubble Tight Dampers can be integrated into any system requiring reliable flow control and shutoff, such as ductwork in ventilation, exhaust lines in power generation, and air management systems in clean room environments. Their customizable sizes ensure compatibility with various installation needs.Q: What is the process for operating the manual damper?

A: Operation is straightforward: the damper is controlled using a manual hand lever or wheel, which requires minimal torque for opening or closing. Position indicators can be included as accessories for precise monitoring of blade status.Q: What are the main benefits of installing a manual bubble tight damper?

A: Key benefits include zero leakage, robust construction, corrosion resistance, and ease of manual operation. With no power consumption and a lifespan of 20+ years, these dampers ensure cost-effective, reliable, and maintenance-friendly flow control in critical applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry