Call: 08071931936

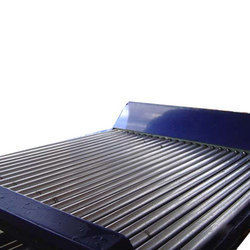

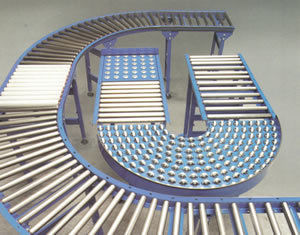

Free Roller Conveyor

15500 INR/Number

Product Details:

- Frame Material Metal

- Rolling Speed Depends on manual push or gravity

- Structure Simple roller structure

- Dimension (L*W*H) Customizable dimensions based on requirements

- Material Steel rollers with metal frame

- Load Capacity Customizable based on roller specifications

- Size Customizable

- Click to View more

X

Free Roller Conveyor Price And Quantity

- 15500 INR/Number

- 1 , , Meter

Free Roller Conveyor Product Specifications

- Not applicable (manual or gravity-driven)

- Depends on size and material

- Material handling transportation

- Customizable based on roller specifications

- Depends on manual push or gravity

- Simple roller structure

- Steel rollers with metal frame

- Metal

- Customizable dimensions based on requirements

- Customizable

- Standard room temperatures (can be customized for specific environments)

Product Description

Free Roller Conveyor

Product details

| Material | Stainless Steel,Rubber |

| Type | Pneumatic Conveyors |

| Length | 60-100 feet,40-60 feet |

| Material Handling Capacity | 150-200 kg per feet,200-300 kg per feet |

Customizable Material Handling Solutions

Our free roller conveyors are engineered for adaptability, offering customizable dimensions and load capacities to fit diverse operational needs. Each unit is constructed with a sturdy metal frame and steel rollers to handle different weights and materials, ensuring robust, long-term performance. These conveyors serve essential roles in improving workflow efficiency in industries across India and abroad.

Manual and Gravity-Driven Efficiency

The absence of a motor in our free roller conveyor design enables simple, maintenance-light material transport using manual force or gravitational pull. This flexibility makes the system ideal for dynamic environments requiring reliable and cost-effective materials movement, while also minimizing energy consumption and maintenance costs.

FAQs of Free Roller Conveyor:

Q: How does the free roller conveyor operate without power?

A: The free roller conveyor uses manual push force or gravitational incline to move materials along the steel rollers. This eliminates the need for motors or electrical power, offering efficient material transportation with minimal operating costs.Q: What benefits does a steel roller with metal frame conveyor offer in material handling?

A: Steel rollers and metal frames provide exceptional strength and durability, ensuring the conveyor can withstand heavy loads and frequent use. This makes them ideal for demanding environments and enhances longevity and reliability in material handling applications.Q: When should I choose a customizable free roller conveyor over a powered conveyor?

A: A free roller conveyor is best suited for situations where material movement occurs over short distances, frequent stops are needed, or where energy savings and simplicity are priorities. They are also selected when specific sizes, loads, or unique layout constraints exist, which powered conveyors may not accommodate as flexibly.Q: Where can these conveyors be installed and utilized?

A: These conveyors can be implemented in warehouses, assembly lines, distribution centers, and manufacturing facilitiesanywhere efficient, manual, or gravity-based transportation of materials is required. They are also suitable for export, with necessary customizations for clients in India and international markets.Q: What is the typical process for customizing a free roller conveyor?

A: Customization involves assessing your operational needs, including desired dimensions, load capacities, and environmental demands. Specifications are matched with roller types and frame materials, ensuring the conveyor precisely suits your workflow and material characteristics.Q: How does the rolling speed vary on a manual or gravity-driven conveyor?

A: Rolling speed is influenced by the manual push force or the steepness of the gravity-driven slope, as well as the weight and size of conveyed items. Speeds can be controlled and optimized based on operational workflow and safety considerations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry