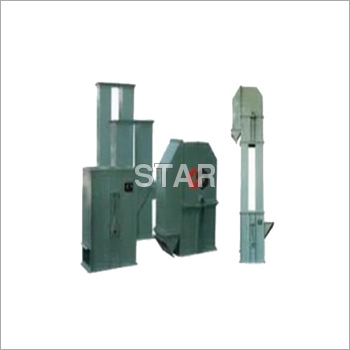

Bucket Elevator

Product Details:

- Structure Vertical

- Dimension (L*W*H) As per model (customized)

- Belt Size Customizable

- Frame Material Mild steel

- Elevating Speed 1.5 to 3.5 m/s

- Belt Type Rubber/ PVC/ Fabric Belt

- Rolling Speed Variable

- Click to View more

Bucket Elevator Price And Quantity

- 45000 INR/Number

- 1 Meter

Bucket Elevator Product Specifications

- As per model (customized)

- Customizable

- Material conveying in food, grain, chemical, agriculture, and cement industries

- Depends on configuration

- 220V/380V/415V

- Vertical

- Variable

- Standard/Customizable

- Mild Steel/ Stainless Steel

- Adjustable as per requirement

- Rubber/ PVC/ Fabric Belt

- Mild steel

- 1.5 to 3.5 m/s

Bucket Elevator Trade Information

- All India

Product Description

Bucket Elevator (Belt type or Chain type)

We offer our clients a wide range of Bucket Elevator. We manufacture these as per the defined industry standards. Our range of Bucket Elevator are ideal for handling hot and abrasive material and are integrated with double strand roller chains that can easily lift the load. Known for strong body and low power consumption, Bucket Conveyors can ensure free flow of Material in diverse conditions. The equipments offered by us in this category are Chain Bucket Elevator and Belt Bucket Elevators, as per casing it can be categorized as twin casing Bucket Elevator and Single Casing Bucket Elevator.

Product details

| Model | Bucket Elevator |

| Material | MS |

| Automation Grade | Automatic |

| Structure | Belt Conveyor |

| Type | Chain/ belt type |

Flexible Design for Varied Applications

Our bucket elevator can be customized with standard or tailored dimensions, accommodating different materials and operational requirements. With its vertical structure and adjustable discharge height, it streamlines bulk material transfer in demanding environments.

Multiple Bucket and Belt Options

Choose buckets made from mild steel, stainless steel, or plastic, along with belts in rubber, PVC, or fabric. This ensures suitability for a wide range of products, matching the needs of food, chemical, grain, and cement handling processes.

Low Noise and Efficient Operation

Equipped with a reliable gear motor and designed for stable operation, the bucket elevator guarantees low noise levels and efficient material conveying. Adjustable cycle times and rolling speeds further enhance process control and productivity.

FAQs of Bucket Elevator:

Q: How is the bucket elevator installed and what is its mounting type?

A: The bucket elevator is installed as a floor-mounted unit, which provides a stable base for vertical material handling. Professional installation ensures optimal alignment and performance in your facility.Q: What are the available options for bucket and belt materials?

A: Buckets are offered in mild steel, stainless steel, or plastic while belts can be customized in rubber, PVC, or fabric. These options allow compatibility with various materials and industries.Q: Where can this bucket elevator be used?

A: The bucket elevator is suitable for material conveying in food, grain, chemical, agriculture, and cement industries, making it versatile for use in factories, processing plants, and warehouses.Q: What feeding methods can I choose for this elevator?

A: You can select between manual feeding or a screw feeder input, allowing integration with existing material handling systems and batch or continuous operation processes.Q: What are the benefits of adjustable discharge height and cycle time?

A: Adjustable discharge height up to 30 meters and customizable cycle time ensure the elevator matches specific processing needs, improving operation efficiency and facilitating integration with other equipment.Q: How does the elevator maintain low noise levels during operation?

A: The elevator is engineered with a gear motor and precision-built components to ensure quiet function, which enhances workplace comfort and complies with industrial noise regulations.Q: What surface treatments are available for durability?

A: You may choose painted, powder-coated, or galvanized surface treatments. These options enhance resistance to corrosion and wear, extending the service life in harsh operational environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry