Call: 08071931936

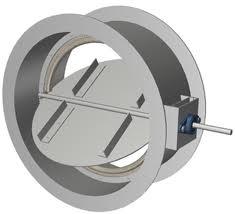

Pneumatic Bubble Tight Dampers

65000 INR/Number

Product Details:

- Usage & Applications HVAC, cleanroom, isolation, process industries, hazardous area ventilation

- Driven Type Pneumatic cylinder

- Speed Pneumatic actuation, response <2 seconds

- Efficiency (%) Up to 99% sealing efficiency

- Source Industrial manufacturer/supplier

- Production Capacity Depends on size and duty cycle

- Accessories Position indicator, solenoid valve, limit switch, mounting flanges

- Click to View more

X

Pneumatic Bubble Tight Dampers Price And Quantity

- 1 , , Meter

- 65000 INR/Number

Pneumatic Bubble Tight Dampers Product Specifications

- No

- 220 V AC

- Varies as per size

- Metallic Grey

- Up to 99% sealing efficiency

- Pneumatic Bubble Tight Damper

- Industrial manufacturer/supplier

- Custom / As per design

- Pneumatic

- Stainless Steel / Mild Steel

- Pneumatic cylinder

- Mount horizontally or vertically to suit duct layout, ensure proper sealing surface

- Pneumatic actuation, response <2 seconds

- Pneumatic Actuated

- Custom as per application

- HVAC, cleanroom, isolation, process industries, hazardous area ventilation

- Position indicator, solenoid valve, limit switch, mounting flanges

- Duct Isolation Damper

- Powder coated / Epoxy painted / Polished

- Depends on size and duty cycle

Product Description

From our extensive range of plate making products, we manufacture, export and supply supreme quality Pneumatic Bubble Tight Dampers. Applicable in numerous industries for separating gases or material from one part to another part, these dampers are available in different sizes and other specific options. For the fabrication of these dampers, our well-versed workforce use premium grade raw material and upgraded technology. These Pneumatic Bubble Tight Dampers are used in various industrial applications for controlling the flow of operation.

Features:

- Corrosion resistance

- High strength

- User friendly design

- Easy to use

Product details

| Type | Motorized / Pneumatic / Manual |

| Size | 100mm to 3000mm |

| Model | Butterfly Dampers |

| Brand | Star Material |

| Material | Mild Steel, Stainless steel |

- Material: 304 Stainless Steel

- Port Size: 3"- 44

- Pressure: 200-400 mm Aq

Unmatched Sealing Performance

Bubble tight dampers are engineered to deliver up to 99% sealing efficiency, ensuring safe and controlled airflow for critical environments like cleanrooms, hazardous area ventilation, and process industries. Their robust construction and advanced seal technology eliminate leakage, keeping operation secure and compliant with stringent standards.

Flexible Design for Diverse Applications

Choose from rectangular or round shapes, with dimensions and capacities fully customizable to match specific installation needs. These dampers support both flanged and welded connections, offering versatility for integration into fume extraction, exhaust systems, or HVAC networks.

Easy Remote Operation and Maintenance

The pneumatic actuation system provides fast, reliable damper response (<2 seconds) using a control panel or remote operation. Design simplicity means minimal maintenancejust periodic actuator checksreducing downtime while maintaining high performance in demanding industrial environments.

FAQs of Pneumatic Bubble Tight Dampers:

Q: How does a pneumatic bubble tight damper ensure high sealing efficiency?

A: These dampers utilize EPDM, silicon, or neoprene gaskets, combined with precise engineering, to achieve up to 99% bubble-tight sealing. This ensures minimal leakage for critical environments such as cleanrooms, hazardous areas, and process industries.Q: What configurations and sizes are available for this damper?

A: The dampers can be supplied in rectangular or round shapes, with dimensions and capacities customized according to application requirements. Connection types include flanged or welded options, accommodating diverse duct layouts.Q: Where can pneumatic bubble tight dampers be installed?

A: These dampers are designed for use in HVAC, cleanroom isolation, hazardous area ventilation, fume extraction, and exhaust systems. They can be mounted horizontally or vertically to suit the duct configuration and ensure effective isolation.Q: What is the process for operating and controlling these dampers?

A: Pneumatic actuators drive the damper, which can be operated remotely or via a dedicated control panel. Accessories like solenoid valves and position indicators facilitate easy and reliable remote control for responsive ventilation management.Q: How often is maintenance required for pneumatic bubble tight dampers?

A: Maintenance is minimal, typically involving periodic checks of the pneumatic actuator to ensure consistent operation. Thanks to durable materials and efficient sealing mechanisms, long-term reliability is assured with minimal upkeep.Q: What benefits do these dampers offer over conventional isolation dampers?

A: Pneumatic bubble tight dampers deliver faster response times, higher sealing efficiency, and robust performance in demanding industrial environments. They help maintain contaminant-free airflows and minimize downtime, which is essential for safety and process control.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry