Call: 08071931936

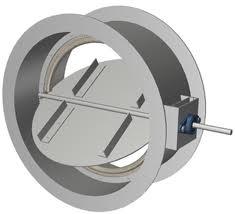

ISOLATION DAMPERS

Product Details:

- Frequency 50/60 Hz (for electric actuators)

- Automation Grade Manual / Motorized

- Speed Manual or as per actuator specification

- Accessories Actuator, Position indicator, Limit switches

- Driven Type Manual lever / Electric or Pneumatic actuator

- Efficiency (%) Up to 98% isolation efficiency

- Usage & Applications Industrial HVAC, Air Handling Units, Clean Rooms, Pharma, Power Plants, Commercial Ventilation

- Click to View more

X

ISOLATION DAMPERS Price And Quantity

- 1

ISOLATION DAMPERS Product Specifications

- Galvanized Iron (GI), Mild Steel (MS), or Stainless Steel (SS)

- Horizontal or vertical mounting, easy retrofit design

- Manual or Motorized

- Standard as per actuator

- OEM / ODM Manufacturer

- Customizable as per duct size or requirement

- Silver / Grey / Customized as per requirement

- Industrial HVAC, Air Handling Units, Clean Rooms, Pharma, Power Plants, Commercial Ventilation

- Industrial HVAC Dampers

- 220V / 380V / 415V (depending on actuation system)

- Hand operated, Electrical actuator, or Pneumatic actuator

- As per actuator specification

- Specified per order/project

- Suitable for low to high air volumes

- As per size and material specification

- Customized as per project

- No

- Isolation Damper

- Manual / Motorized

- Powder coated, Painted, or GI finish

- 50/60 Hz (for electric actuators)

- Depend on actuator type

- Low leakage, Robust construction, Corrosion resistant coating, Smooth operation

- Up to 98% isolation efficiency

- Manual or as per actuator specification

- Lever, Pneumatic, or Electric actuator based

- Actuator, Position indicator, Limit switches

- Manual lever / Electric or Pneumatic actuator

Product Description

We a well-known manufacturer, exporter and supplier in the domain, engaged in offering excellent quality Isolation Dampers. These dampers are used for separating waste material from the goods and control the flow of water. Under experts' visionary guidance, our provided dampers are intricately manufactured by utilizing supreme quality components and high-end technology in conformity with the set market norms. Tested on certain quality parameters, we provide these Isolation Dampers in different specified and customized options at pocket-friendly prices within given time frame.

Features:

- Unmatchable performance

- Low power consumption

- Easy to operate

- Precisely engineered

Engineered for Versatility and Performance

Our isolation dampers accommodate virtually any duct size with customizable dimensions, seamless compatibility, and installation in either horizontal or vertical orientations. With frame thickness options from 1.2 to 3 mm and a choice of finishespowder-coated, painted, or GIthey provide impressive durability and corrosion resistance for demanding industrial HVAC applications.

Superior Airtightness and Low Leakage

Constructed to achieve Class 2 or better leakage performance as per EN 1751, these dampers utilize neoprene or EPDM rubber edges to ensure high air tightness. Their dependable sealing minimizes energy losses, maximizes system efficiency, and helps maintain critical environmental conditions in spaces such as clean rooms and laboratories.

FAQs of ISOLATION DAMPERS:

Q: How does the isolation damper ensure airtight sealing and minimal leakage?

A: The isolation damper uses neoprene or EPDM rubber edges to provide a tight seal along with precise construction adhering to EN 1751 Class 2 or better, significantly reducing air leakage and maintaining high airtightness in HVAC systems.Q: What types of actuation and operating controls are available for these isolation dampers?

A: Isolation dampers are available with manual lever control, pneumatic, or electric actuators, enabling either manual or motorized operation. This allows for flexible integration into various HVAC setups according to project needs.Q: When and where should isolation dampers be installed for maximum effectiveness?

A: Isolation dampers are best installed in air handling units, clean rooms, pharmaceutical facilities, power plants, and commercial ventilation systems, particularly where reliable air isolation and high airtightness are essential. Installation can be either horizontal or vertical, depending on site requirements.Q: What is the process for maintaining isolation dampers, and is frequent inspection required?

A: These dampers require minimal maintenanceonly periodic inspection is recommended to ensure continued performance of the sealing edge and actuator. Routine checks help sustain airtightness and long-term durability, reducing downtime.Q: What benefits do isolation dampers offer to HVAC and industrial ventilation systems?

A: Isolation dampers provide robust construction, high isolation efficiency (up to 98%), low leakage, and corrosion resistance, ensuring reliable operation. These features help optimize air quality, conserve energy, and maintain regulatory compliance in demanding applications.Q: Can the dimensions and surface finish be customized according to specific project requirements?

A: Yes, both the dimensions (length, width, and height) and surface finish (powder coated, painted, or GI) can be tailored to fit project specifications and enhance compatibility with existing ductwork and system aesthetics.Q: Are isolation dampers suitable for retrofitting existing HVAC systems?

A: Indeed, their easy retrofit design allows for seamless integration into both new and existing HVAC installations, offering flexibility and convenience for upgrades or replacements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry