Call: 08071931936

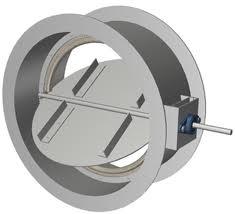

LOUVER DAMPERS

Product Details:

- Speed Depend on drive type

- Frequency 50 Hz / 60 Hz (for electric actuation)

- Production Capacity As per customer requirements

- Installation Guideline To be installed in line with duct/flue, with proper sealing

- Accessories Actuator, position indicator, limit switch, mounting flanges

- Model No Custom/Standard as per manufacturer

- Temperature Range Upto 400C (custom design for higher temps possible)

- Click to View more

X

LOUVER DAMPERS Product Specifications

- Grey/Metallic/Silver (custom coated/painted as per request)

- Louver Damper

- Rugged construction, corrosion resistant, high efficiency, low leakage

- Mild Steel (MS), Stainless Steel (SS)

- Handles airflow up to 50,000 CFM (depends on model size)

- Air Flow Control Damper

- 50 Hz / 60 Hz (for electric actuation)

- Powder coated / painted / galvanized / SS finish

- Depend on drive type

- Upto 400C (custom design for higher temps possible)

- 220V / 380V (for actuated types)

- Pneumatic / Electric / Manual Lever

- Varies as per size and material, from 12 kg onwards

- No

- Manual, Gear, Pneumatic, Electric

- Manufacturer/Factory Supply

- As per customer requirements

- Custom/Standard as per manufacturer

- Actuator, position indicator, limit switch, mounting flanges

- Gear/Lever Driven, Pneumatic Operation (customizable)

- Up to 90% sealing efficiency

- To be installed in line with duct/flue, with proper sealing

- Customizable as per requirements, e.g. 400x400 mm up to 2000x2000 mm

Product Description

Our enterprise has gained immense recognition in manufacturing, exporting and supplying quality assured array of Louver Dampers that comes with stationary blades into one common frame. These dampers are manufactured with cutting-edge technology in order to meet set international standards at our well-equipped manufacturing unit. Used for controlling the flow of liquid, these Louver Dampers are extensively appreciated and demanded in the market due to its rugged design and excellent performance.

Features:

-

Cost-effective performance

-

Power efficient

-

Easy operation

-

Trouble-free functioning

Versatile and Robust Airflow Control

Louver dampers are engineered to manage airflow efficiently in both horizontal and vertical orientations. Their customizable blades and sizes make them suitable for various HVAC and process systems. The durable construction resists corrosion, while high-capacity handling and exceptional sealing efficiency contribute to optimal environmental control in demanding industrial or commercial settings.

Tested for Performance and Compliance

Each louver damper undergoes rigorous factory testing to ensure minimal leakage and reliable performance. Designed to meet global standards (IS, DIN, ASTM, ASME), these dampers provide assurance of quality and safety. Accessory options such as actuators, position indicators, and limit switches further enhance operational monitoring and control.

Customizable to Your Specifications

From blade count to dimensions and control types, these dampers are tailored as per customer requirements. The operating pressure, temperature range, and mounting options allow seamless integration into new or existing ductwork. Surface finishes, colors, and material choices add to their adaptability, matching varied installation environments.

FAQs of LOUVER DAMPERS:

Q: How do louver dampers achieve a low leakage rate in ventilation systems?

A: Louver dampers are precision-engineered and factory-tested to deliver a maximum 1% leakage rate at full differential pressure. Their robust construction, high-quality materials, and tight blade sealing mechanisms help minimize air loss, ensuring efficient airflow management in industrial and commercial applications.Q: What control options are available for operating these louver dampers?

A: These dampers are available with multiple control options, including manual levers, pneumatic actuators, and electric actuators. The choice of control system can be matched to your operational preferences or automated systems, supporting voltages of 220V or 380V (for actuated types) and drive types such as gear or lever driven.Q: When is it necessary to customize the blade number or dimensions of a louver damper?

A: Customization becomes essential when the application requires specific airflow capacities, mounting conditions, or duct/flue sizes. The number of blades and overall dimensions are tailored to match your system requirements, ensuring optimal sealing efficiency and airflow regulation tailored to each project.Q: Where should louver dampers be installed for optimal performance?

A: Louver dampers should be installed inline with ductwork or flues, with attention to proper sealing and orientation (horizontal or vertical) as per the system design. Standard installation guidelines recommend secure mounting with accessory fittings like position indicators and limit switches for efficient operation and monitoring.Q: What is the process for selecting the right louver damper for my facility?

A: Selecting the correct louver damper involves assessing your airflow requirements (up to 50,000 CFM), operating pressure, temperature range, mounting orientation, material preference, control method, and compliance standards. Expert guidance from the manufacturer ensures compatibility with your ventilation system and maximizes operational benefits.Q: How do louver dampers benefit industrial and commercial environments?

A: Louver dampers enhance airflow control efficiency, maintain environmental safety, and reduce energy loss due to their low leakage and high sealing capabilities. Their rugged, corrosion-resistant construction ensures long-term reliability and cost-effective operation, especially in demanding HVAC and process applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry