Call: 08071931936

Assembly Line Belt Conveyor

95000.00 INR/Number

Product Details:

- Surface Finish Powder Coated

- Thickness 2-6 mm (Belt)

- Belt Type Flat Belt

- Features Durable, Easy to Operate, Low Maintenance

- Power Source Electric

- Material Mild Steel Frame, PVC/Rubber Belt

- Type Assembly Line Belt Conveyor

- Click to View more

X

Assembly Line Belt Conveyor Price And Quantity

- 95000.00 INR/Number

- 1 , , Meter

- < 60 dB

- Optional

- 300-1000 mm

- -10°C to +60°C

- Floor Mounted

- Provided as Required

- Customizable (Standard up to 20 meters)

- Gear Motor Driven

- Included with Emergency Stop

Assembly Line Belt Conveyor Product Specifications

- Corrosion Resistant, Heat Resistant

- 0.5-2 m/s (Adjustable)

- 1-3 HP

- Mild Steel Frame, PVC/Rubber Belt

- No

- Assembly Line Belt Conveyor

- Powder Coated

- Optional Attachment

- Assembly Lines, Manufacturing, Packaging

- Electric

- No

- 100-300 kg per meter

- 220-240 V

- 2-6 mm (Belt)

- Belt Conveyor with Supporting Frame

- Yes

- Durable, Easy to Operate, Low Maintenance

- Flat Belt

- < 60 dB

- Optional

- 300-1000 mm

- -10°C to +60°C

- Floor Mounted

- Provided as Required

- Customizable (Standard up to 20 meters)

- Gear Motor Driven

- Included with Emergency Stop

Product Description

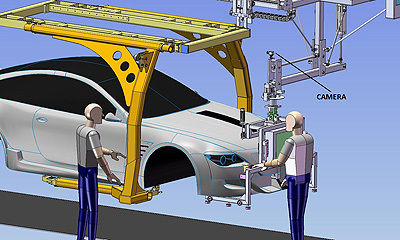

Assembly Line Belt Conveyor

Product details

|

Structure |

Belt Conveyor |

|

Material |

Stainless Steel,Rubber,Plastic |

|

Brand |

Star Material |

|

Belt Width |

20-30 inch,30-40 inch |

|

Operating Speed |

2-3 m/s,3-4 m/s |

|

Length |

20-40 feet,40-60 feet,60-100 feet |

|

Capacity |

150-200 kg per feet,200-300 kg per feet |

Versatility and Customization

This assembly line belt conveyor is available in various widths (300 mm1000 mm) and customizable lengths, allowing for a tailored fit in diverse industrial setups. With optional height adjustment and side rails, the system caters to specific process requirements, enhancing operational flexibility and overall productivity.

Superior Durability and Safety

Constructed with a robust mild steel frame and a powder-coated finish, the conveyor is designed to withstand corrosion and high temperatures. The integrated control panel with an emergency stop ensures safety for operators, while the reliable gear motor drive provides consistent and quiet performance during prolonged usage.

Effortless Maintenance and Operation

Featuring a flat PVC or rubber belt and a simple gear motor-driven mechanism, the conveyor is easy to operate and maintain. Optional roller conveyor attachments and low-maintenance design make it ideal for assembly, manufacturing, and packaging applications. Its efficient system reduces downtime and boosts production efficiency.

FAQs of Assembly Line Belt Conveyor:

Q: How can I customize the length and width of the assembly line belt conveyor to fit my workspace?

A: You can specify the required belt width, ranging from 300 mm to 1000 mm, and the length, which can be customized up to 20 meters. Our team will assist you in designing a conveyor that fits your workspace dimensions and operational needs.Q: What are the benefits of using a gear motor-driven belt conveyor system in assembly lines?

A: A gear motor-driven system ensures steady and adjustable speed (0.52 m/s), smooth power delivery, and reduced noise levels (<60 dB), making it ideal for continuous operation in assembly lines while minimizing worker fatigue and environmental disruptions.Q: When should I consider using optional attachments like roller conveyors or height adjustment?

A: Optional attachments such as roller conveyors or height adjustment are recommended when your assembly process requires flexible material flow or varying conveyor heights to match different workstation levels, thereby enhancing ergonomic efficiency and process integration.Q: Where is this belt conveyor typically installed, and what are the installation requirements?

A: These conveyors are usually floor-mounted within manufacturing, packaging, or assembly plant environments. The installation requires a flat, stable surface and access to a standard 220-240V electric power supply for optimal performance.Q: What safety features are included with the assembly line belt conveyor?

A: The conveyor is equipped with a control panel featuring an emergency stop button. Additionally, side rails can be provided as required to prevent product spillage, ensuring safe operational conditions at all times.Q: How does the corrosion and heat resistance of the conveyor benefit long-term use?

A: The powder-coated mild steel frame and specialized belt materials (PVC or rubber) confer corrosion and heat resistance, which means the conveyor can endure harsh industrial environments and fluctuating temperatures (-10C to +60C), extending its lifespan and reducing maintenance needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry