Call: 08071931936

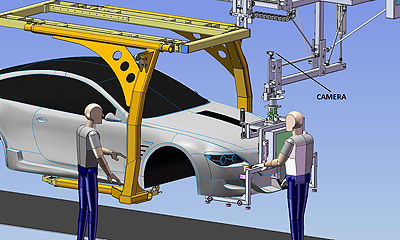

Automotive Assembly Line Conveyor

15500 INR

Product Details:

- Belt Type Anti-static, oil & heat resistant belts available

- Power Source Electric motor-driven

- Features Heavy-duty build, modular design, easy installation, low maintenance, customizable length and width

- Surface Finish Powder coated / painted / chrome plated

- Thickness Frame thickness 3 mm to 5 mm, belt thickness 2 mm to 3.5 mm

- Material Mild steel or stainless steel with powder-coated/painted finish

- Type Automotive Assembly Line Conveyor

- Click to View more

X

Automotive Assembly Line Conveyor Price And Quantity

- 15500 INR

- 1 Meter

- Length, width, speed, and elevation tailored to customer requirements

- Adjustable, typically 500 mm to 1200 mm

- Emergency stop switches, side rails, and overload protection

- Operates efficiently in -10°C to +55°C environments

- Designed for continuous industrial operation

- PLC-based automation with HMI control panel

- On-site assembly and commissioning

- <72 dB during operation

- Low-maintenance, easy-to-access components

Automotive Assembly Line Conveyor Product Specifications

- Anti-static, oil & heat resistant belts available

- Heavy-duty build, modular design, easy installation, low maintenance, customizable length and width

- Electric motor-driven

- Corrosion and wear-resistant construction

- Not applicable for standard automotive assembly line conveyors

- 380V/415V, 3 Phase, 50Hz

- Powder coated / painted / chrome plated

- Automotive Assembly Line Conveyor

- 520 meters per minute (adjustable)

- Available with PVC or PU belts

- Up to 2000 kg per conveyor section

- Gravity or powered, as per application

- 2.2 kW to 7.5 kW per drive unit

- Used in automotive assembly plants for transporting vehicle components and assemblies

- Modular steel frame with heavy-duty support legs

- Optional integration with vertical lift modules

- Mild steel or stainless steel with powder-coated/painted finish

- Frame thickness 3 mm to 5 mm, belt thickness 2 mm to 3.5 mm

- Length, width, speed, and elevation tailored to customer requirements

- Adjustable, typically 500 mm to 1200 mm

- Emergency stop switches, side rails, and overload protection

- Operates efficiently in -10°C to +55°C environments

- Designed for continuous industrial operation

- PLC-based automation with HMI control panel

- On-site assembly and commissioning

- <72 dB during operation

- Low-maintenance, easy-to-access components

Product Description

Buy Online our new Automotive Assembly Line Conveyor, a best-seller recognized for its unrivaled reliability and stellar performance. Featuring terrific customization options for length, width, speed, and elevation, every unit is engineered to suit your requirements. Enhanced by a PLC-based control system and HMI panel, this conveyor operates at noise levels below 72 dB, with a corrosion-resistant, heavy-duty modular frame. Benefits include adjustable height, low maintenance, and load capacities up to 2000 kg. Installation is onsite, and vertical integration modules are available. Order from an exporter, manufacturer, supplier, and trader in India today!

Automotive Conveyor Application & Material Features

This Automotive Assembly Line Conveyor is used in automotive assembly plants for seamlessly transporting vehicle components and assemblies. The application method involves efficient, continuous industrial operation with quick customization of conveyor dimensions. Made from mild steel or stainless steel, with a powder-coated or painted finish, its structure ensures strength and durability. Material features include corrosion and wear resistance, while anti-static, oil, and heat-resistant belts suit various assembly applications, ensuring optimal performance across challenging work environments.

Certifications, Quick Dispatch & Supply Assurance

Our Automotive Assembly Line Conveyor adheres to leading industrial certifications, guaranteeing quality construction and safety. Order completion is prompt, with FOB Port options available for fast logistics and export requirements. Valuation and supply ability meet high industry standardsensuring quick dispatch and reliable service whether youre a manufacturer, supplier, or exporter. Trust in our streamlined process for timely delivery and installation, supporting continuous operations and long-term productivity in automotive plants.

Automotive Conveyor Application & Material Features

This Automotive Assembly Line Conveyor is used in automotive assembly plants for seamlessly transporting vehicle components and assemblies. The application method involves efficient, continuous industrial operation with quick customization of conveyor dimensions. Made from mild steel or stainless steel, with a powder-coated or painted finish, its structure ensures strength and durability. Material features include corrosion and wear resistance, while anti-static, oil, and heat-resistant belts suit various assembly applications, ensuring optimal performance across challenging work environments.

Certifications, Quick Dispatch & Supply Assurance

Our Automotive Assembly Line Conveyor adheres to leading industrial certifications, guaranteeing quality construction and safety. Order completion is prompt, with FOB Port options available for fast logistics and export requirements. Valuation and supply ability meet high industry standardsensuring quick dispatch and reliable service whether youre a manufacturer, supplier, or exporter. Trust in our streamlined process for timely delivery and installation, supporting continuous operations and long-term productivity in automotive plants.

FAQs of Automotive Assembly Line Conveyor:

Q: How can the Automotive Assembly Line Conveyor be customized for my facility?

A: The conveyor allows customization of length, width, speed, and elevation to match your exact production layout and throughput requirements. These options are discussed during the project evaluation and are tailored to maximize your facilitys operational efficiency.Q: What is the process for on-site installation and commissioning?

A: After order confirmation, our expert team arrives at your facility for on-site assembly and commissioning, ensuring seamless integration with your existing automotive assembly line and minimal disruption to operations.Q: When is vertical conveyor integration beneficial to use?

A: Vertical conveyor integration is ideal when you need to transport components between different floor levels within your assembly plant, optimizing space usage and workflow efficiency.Q: Where can this conveyor be used, and what working environments does it support?

A: The conveyor is designed for continuous operation in automotive assembly plants, functioning efficiently in ambient temperatures ranging from -10C to +55C, and is built to withstand harsh industrial working conditions.Q: What safety features are included with the conveyor system?

A: The conveyor boasts stellar safety measures, such as emergency stop switches, side rails, and overload protection, ensuring a secure working environment and compliance with industrial standards.Q: How does the corrosion and wear resistance benefit my operation?

A: With corrosion and wear-resistant construction, the conveyor provides extended lifespan, reduced maintenance downtime, and reliable performance, even in demanding automotive production environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry