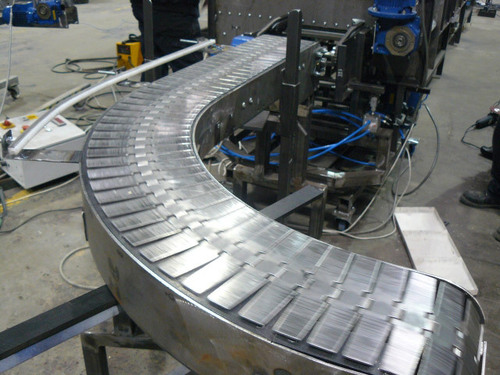

SLAT CONVEYORS

Product Details:

- Thickness Slat thickness 310 mm

- Features Custom design, modular construction, smooth operation

- Belt Type Slat type (Wooden/Metal/Plastic slats as per application)

- Surface Finish Powder Coated / Painted

- Power Source Electric

- Material Mild Steel / Stainless Steel

- Type Slat Conveyor

- Click to View more

SLAT CONVEYORS Price And Quantity

- 45000 INR/Number

- 1 , , Meter

SLAT CONVEYORS Product Specifications

- Mild Steel / Stainless Steel

- No

- Up to 2000 kg per hour

- Electric

- No

- 220V / 380V

- Powder Coated / Painted

- Mild Steel frame

- Corrosion Resistant, Heat Resistant

- Material handling in assembly lines, automotive, packaging, and warehousing

- Slat type (Wooden/Metal/Plastic slats as per application)

- Custom design, modular construction, smooth operation

- No

- No

- Slat thickness 310 mm

- Slat Conveyor

Product Description

Comprehensive mix of market understanding and modern technology enables us to manufacture, export and supply a quality assortment of Slat Conveyors. These conveyors are used in various industries to transport material like fines, small parts, small chips and stampings from one place to another. The offered conveyors are manufactured under the stern supervision of our technical experts utilizing fine grade raw materials with the aid of advanced manufacturing techniques as per the latest industry standards. These Slat Conveyors are available for our clients in various technical specifications and at affordable rates.

Features:

- Rugged structure

- High performance

- Less maintenance

- Low energy consumption

Product details

| Material | Rubber ,Stainless Steel |

| Material Handling Capacity | 100-150 kg per feet,150-200 kg per feet |

| Length | 20-40 feet,40-60 feet |

| Type | Chain Conveyor |

Versatile Design for Diverse Applications

With customizable slat widths, adjustable heights, and lengths up to 30 meters, SLAT CONVEYORS cater to a wide range of industrial needs, including assembly lines, automotive production, packaging, and warehousing. Their modular design allows flexibility for handling various materials efficiently and safely, making them suitable for both large and small-scale operations.

Durable and Reliable Construction

Built with mild steel or stainless steel frames and powder-coated or painted surfaces, these conveyors are both corrosion and heat resistant. The slat belt, available in wood, metal, or plastic, ensures sturdy material transfer while maintaining low noise levels. Operating up to 100C and supporting up to 2000 kg per hour, they offer reliable performance in demanding environments.

Automated Control for Enhanced Productivity

Each SLAT CONVEYOR comes equipped with a user-friendly control panel enabling ON/OFF switching and speed variation. This system facilitates precise control over material flow and operational speed, supporting streamlined processes, reducing manual intervention, and improving productivity in industrial settings.

FAQs of SLAT CONVEYORS:

Q: How can I customize a SLAT CONVEYOR for my specific application?

A: SLAT CONVEYORS can be tailored with slat widths from 100 to 800 mm, adjustable conveyor heights, and lengths up to 30 meters. Options for slat material include wood, metal, or plastic, and you can select surface finish and frame material based on your environment and usage needs.Q: What is the process for installation of SLAT CONVEYORS?

A: Installation involves floor mounting or placing on supports, depending on your facility layout. The conveyors feature modular construction, making assembly straightforward. The included control panel requires standard 220V/380V electric connections, and our team offers guidance to ensure a safe and efficient setup.Q: When should SLAT CONVEYORS be used over other conveyor types?

A: SLAT CONVEYORS are ideal when you need precise, smooth handling of heavy or shaped items in environments where corrosion resistance, heat tolerance, and low noise are essential. They outperform other conveyors in industries like automotive, packaging, and assembly lines requiring stable and customizable platforms.Q: Where are SLAT CONVEYORS typically installed in industrial environments?

A: These conveyors are commonly installed in assembly lines, packaging plants, automotive workshops, and warehousing areas where controlled material movement is crucial. Their capacity to be floor mounted or placed on supports ensures flexibility across diverse operational settings.Q: What benefits does the included control panel offer?

A: The integrated control panel allows for easy ON/OFF operation and speed adjustments, giving users complete control over conveyor movement. This enhances workflow efficiency, adaptability to different processes, and minimizes downtime during operation.Q: Are SLAT CONVEYORS suitable for handling high-temperature materials?

A: Yes, the conveyors are designed to operate at temperatures up to 100C and feature slats and frames resistant to heat and corrosion, making them suitable for conveying materials in demanding industrial conditions.Q: What types of materials can the slat belt be made from?

A: Depending on your application, the slat belt can be constructed from wood, metal, or plastic. Each option is selected to match the specific handling requirements, durability, and environmental conditions of your operational setting.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry