Call: 08071931936

Guillotine Gates

Product Details:

- Bore Customizable as required

- Lifting Height As per specification

- Power Source Manual, Pneumatic, or Electric

- Chain Length As per requirement

- Diameter Custom sizes available

- Load Capacity Up to 10 tons, depending on design

- Application Isolation and control of bulk material flow in hoppers, bins, silos, and chutes

- Click to View more

X

Guillotine Gates Price And Quantity

Guillotine Gates Product Specifications

- Up to 10 tons, depending on design

- Custom sizes available

- Isolation and control of bulk material flow in hoppers, bins, silos, and chutes

- Customizable as required

- Manual, Pneumatic, or Electric

- As per specification

- Mild Steel (MS), Stainless Steel (SS)

- As per requirement

Product Description

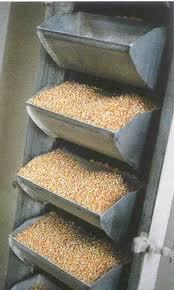

Being in the market for 7 years and serving with our high grade products, we are offering high quality Guillotine Gates. These gates are manufactured at our advanced manufacturing unit under the guidance of our skilled team of professionals with the help of contemporary technology and by making use of optimum quality raw materials. Provided gates are perfect for dividing partitions inside the shed. Clients can avail these Guillotine Gates from us in various sizes and capacities as per their requirements and at reasonable rates.

Features:

-

Corrosion proof coating

-

Rugged structure

-

Less maintenance

-

Excellent finish

Versatile Operation for Bulk Material Control

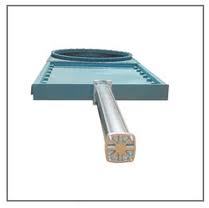

Guillotine Slide Plate Gates excel in isolating and regulating bulk flow in diverse applications, such as hoppers and silos. Operators can choose manual, pneumatic, or electric actuation methods, ensuring seamless integration for different process requirements. Built for durability, these gates are engineered to suit custom dimensions and load capacities, adapting effortlessly to specific operational standards.

Customizable Design for Your Process Needs

With flexible options in size, material, and connection types, these gates accommodate a range of industry demands. Whether your process involves extreme temperatures or heavy loads, the gates can be crafted with powder-coated or painted frames in mild or stainless steel. Control choicespush button, local lever, or remotefurther enhance process accuracy and safety.

FAQs of Guillotine Gates:

Q: How do Guillotine Slide Plate Gates operate in industrial bulk material systems?

A: Guillotine Slide Plate Gates control the flow and isolate bulk materials within hoppers, bins, silos, and chutes by moving a flat plate across the opening. Operation can be manual via a hand wheel, automatic using pneumatic cylinders, or electric actuators, depending on process requirements.Q: What are the main benefits of using these gates for material isolation and control?

A: These gates provide reliable isolation, efficient flow regulation, and can withstand demanding conditions such as high loads (up to 10 tons) and elevated temperatures (up to 300C). Their customizable design ensures optimal performance in various industrial applications.Q: Where are Guillotine Slide Plate Gates commonly installed?

A: They are typically installed in bulk handling systemssuch as under hoppers, within silos, or at chute outletswhere precise control and isolation of materials like powders, granules, or aggregates is necessary for process integrity and safety.Q: What control options are available for operating the slide plate gate?

A: Users can select from push button control panels, local lever operation, or remote control systems. This variety allows users to integrate the gates into existing automation networks or maintain simple manual control when preferred.Q: How is the gates size and bore customized to fit specific applications?

A: Gate sizes are available from 150 mm to 2000 mm width, with diameters and bore dimensions tailored according to process specifications. This customization ensures compatibility with a range of material types, flow rates, and installation requirements.Q: What process and operating conditions can these gates handle?

A: Designed for ambient or process-specific pressures and temperatures up to 300C, these gates are suitable for harsh industrial environments. Materials like mild steel or stainless steel, along with different finishes, provide resilience against corrosion and wear.Q: Who provides Guillotine Slide Plate Gates and how can I source them in India?

A: These gates are available from established exporters, manufacturers, suppliers, and traders throughout India. Interested buyers can specify operational and design parameters to ensure a solution tailored to their exact bulk material handling needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry