Call: 08071931936

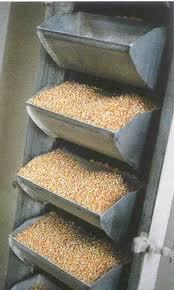

Bulk Handling Conveyors

Product Details:

- Sling Type Steel Chain Sling

- Bore 50 mm

- Mounting Type Floor Mounted

- Number Of Grooves Single/Multiple

- Diameter 400 mm

- Application Industrial Bulk Material Handling

- Chain Length 10 m

- Click to View more

X

Bulk Handling Conveyors Product Specifications

- Steel Chain Sling

- 50 mm

- Single/Multiple

- Floor Mounted

- 400 mm

- Industrial Bulk Material Handling

- 10 m

- Heavy Duty Ball Bearing

- Electric

- Mild Steel

- 8 m

- Head, Tail, Snub

- 2500 kg/hr

Product Description

Since 2007, we are instrumental in manufacturing, exporting and supplying a wide assortment of Bulk Handling Conveyors. We manufacture these conveyors under the strict supervision of our dexterous professionals with the help of contemporary techniques and using raw material. Widely used in packaging, agricultural, textile and many other industries for handling bulk material, these Bulk Handling Conveyors are stringently tested on different parameters in order to ensure its effective functioning.

Features:

-

Maintenance free

-

High production capacity

-

Low power consumption

-

Longer service life

Durable Design for Demanding Operations

Crafted from powder-coated mild steel and equipped with heavy-duty ball bearings, these conveyors are built to withstand harsh industrial environments. The robust frame finish enhances resistance to wear and corrosion, making them ideal for continuous use in bulk material handling applications.

Efficient and Versatile Bulk Transport

With maximum speeds of 120 m/min and load capacities up to 2500 kg/hr, these conveyors efficiently manage high-volume operations. The chain and belt options, along with adjustable incline levels up to 30 degrees, provide customized solutions for varied bulk transportation requirements.

Low Noise, Reliable Performance

Operating below 75 dB, the conveyors are suitable for settings where noise must be minimized. Their motorized drive and screw-type tensioning ensure smooth, consistent operation, while the electric power source delivers dependable performance across multiple industrial settings in India.

FAQs of Bulk Handling Conveyors:

Q: How are these bulk handling conveyors typically installed?

A: These conveyors are floor-mounted for stability and security, making them ideal for heavy-duty industrial environments. Professional installation is recommended to ensure proper alignment and function, especially given their robust construction and high load capacity.Q: What types of materials can be transported using these conveyors?

A: Designed for industrial bulk material handling, these conveyors effectively transport a wide range of materials, including aggregates, grains, coal, ores, and other heavy or continuous bulk loads.Q: When should I choose a belt conveyor over a chain conveyor?

A: Belt conveyors are suitable for transporting finer, non-abrasive materials at higher speeds, while chain conveyors are preferred for heavy, abrasive, or irregularly shaped items. Selection depends on the material type, operational speed requirements, and specific usage conditions.Q: Where are bulk handling conveyors commonly used?

A: These conveyors are widely utilized in industrial applications such as mining, cement plants, power stations, and warehouses across India, wherever continuous movement of bulk materials is essential.Q: What is the process for maintaining these conveyors?

A: Routine maintenance involves checking the screw-type tensioning system, lubricating the heavy-duty ball bearings, inspecting the painted or powder-coated surfaces for wear, and ensuring the drive and pulleys are functioning correctly for reliable, long-term operation.Q: How does the powder-coated finish benefit the conveyor system?

A: The powder-coated finish enhances the conveyors durability by providing superior resistance to corrosion, moisture, and abrasive materials, significantly extending its service life in demanding industrial environments.Q: What advantages does the motorized drive offer in these conveyors?

A: A motorized drive ensures consistent, high-efficiency operation with precise speed control. This minimizes downtime, allows for smooth handling of heavy loads, and supports continuous-duty requirements typical in industrial bulk material handling.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry