Call: 08071931936

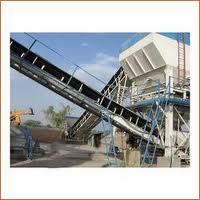

Assembly Conveyors

Product Details:

- Belt Type Flat Belt, Cleated Belt, Modular Belt options

- Power Source Electric

- Surface Finish Powder Coated / Matt / Mirror Finish

- Material Mild Steel / Stainless Steel / Aluminum

- Type Assembly Conveyor

- Structure Modular Frame with Adjustable Supports

- Belt Conveyor Available (PVC, PU, or Rubber options)

- Click to View more

X

Assembly Conveyors Price And Quantity

- 1

Assembly Conveyors Product Specifications

- Available (Gravity or Powered rollers)

- Flat Belt, Cleated Belt, Modular Belt options

- Assembly Conveyor

- 220V / 380V / 415V (as per client specification)

- Powder Coated / Matt / Mirror Finish

- Modular Frame with Adjustable Supports

- Available (PVC, PU, or Rubber options)

- Electric

- Up to 1000 kg/mtr (customizable as per requirement)

- Mild Steel / Stainless Steel / Aluminum

- Assembly Line, Automotive, Electronic, Packaging, and Manufacturing Industries

- Adjustable: 0.5 m/s to 2.5 m/s

- Corrosion Resistant and Wear Resistant

- 0.5 HP to 5 HP (depends on model and length)

Product Description

With the help of our team of technical professionals, we are engaged in offering superior quality Assembly Conveyors. Our provided conveyors are widely used in various industries such as food processing, textile, pharmaceuticals, chemical and many more for transmitting material. Offered conveyors are manufactured with the utilization of premium quality components and advanced technology which ensure its smooth functioning. Clients can avail these stringently examined Assembly Conveyors in different technical options at affordable prices.

Features:

- Low power consumption

- Hassle-free operation

- Negligible maintenance

- Longer service life

Engineered for Versatility

Designed to match a wide array of industrial requirements, our assembly conveyors come with fully customizable dimensions and load capacities. The adjustable height and modular structure provide outstanding flexibility, making integration into your existing workflow seamless, whether youre in automotive, electronics, packaging, or general manufacturing.

Robust Performance and Safety

Manufactured using high-quality mild steel, stainless steel, or aluminum, these conveyors feature corrosion and wear-resistant finishes. Safety remains paramount with built-in emergency stop switches and protective covers, all while maintaining low operational noise and meeting strict industrial safety norms.

Smart Controls and Adaptable Speed

Our systems offer both manual and automated PLC-based controls, allowing precise management of operations. The conveyor speed is fully adjustable from 0.5 m/s to 2.5 m/s, ensuring compatibility with a variety of workflows and throughput demands in any assembly application.

FAQs of Assembly Conveyors:

Q: How do I select the appropriate conveyor width and height for my facility?

A: You can customize the conveyor width (300 mm to 1200 mm) and height (750 mm to 1100 mm) to match your workspace and product requirements. We recommend assessing your assembly line layout, product dimensions, and ergonomic preferences before determining the most suitable configuration.Q: What materials are used in constructing the assembly conveyor, and how are they beneficial?

A: The conveyor structure is available in mild steel, stainless steel, or aluminum with powder coated, matt, or mirror surface finishes. These materials provide excellent corrosion and wear resistance, ensuring longevity and suitability for harsh industrial environments.Q: When should I consider manual versus automated PLC-based controls?

A: Manual controls are ideal for straightforward operations or smaller facilities, while automated PLC-based controls are best suited for high-volume or complex assembly lines requiring precise and consistent speed and process control.Q: Where can these conveyors be used, and which industries are they suitable for?

A: Our assembly conveyors are designed for use in industrial settings such as assembly lines, automotive production, electronic manufacturing, packaging facilities, and general manufacturing environments throughout India and globally.Q: What safety mechanisms are integrated into the conveyor system?

A: The system includes emergency stop switches, protective covers, fixed or adjustable side guides, and conforms to standard industrial safety norms, providing enhanced operational safety for workers.Q: How is the conveyor speed and power configured to meet specific requirements?

A: Conveyor speed is adjustable from 0.5 m/s to 2.5 m/s, with power ratings between 0.5 HP and 5 HP depending on the model and length. This allows customization based on workload, material type, and desired throughput.Q: What are the key benefits of using your assembly conveyor systems?

A: Our conveyors offer customizable design, high load capacity (up to 1000 kg/mtr), low noise operation, durable construction, resistance to corrosion and wear, and integration with both manual and automated control systemsmaximizing efficiency and safety across diverse industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry