Call: 08071931936

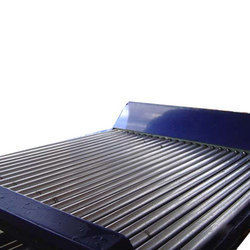

Roller Rack

Product Details:

- Structure Modular Rack System

- Belt Type No belt, uses rollers

- Frame Material Heavy Duty Steel

- Rolling Speed Manual push, depends on operator

- Dimension (L*W*H) 1200 mm x 600 mm x 2000 mm (example size, customizable)

- Material Mild Steel, Powder Coated

- Load Capacity 50 kg per level

- Click to View more

X

Roller Rack Product Specifications

- Heavy Duty Steel

- 1200 mm x 600 mm x 2000 mm (example size, customizable)

- Not required (manual operation)

- No belt, uses rollers

- Mild Steel, Powder Coated

- -10C to 50C

- Modular Rack System

- Approx. 3045 kg/unit

- 50 kg per level

- Customizable as per requirement

- Manual push, depends on operator

- Material Handling, Storage, Warehousing

Product Description

Capitalise on our best-seller Roller Rack, engineered for seamless material handling in industrial settings, logistic hubs, supermarkets, and workshops. With towering adjustability in shelf height and wondrous load capacity (up to 50 kg per layer), this blue-ribbon flow rack supports 37 custom layers. Built with corrosion-resistant zinc-plated steel or plastic rollers, powder-coated mild steel frames, and an easy boltless assembly, it offers reliable performance at the lowest price. Customisable sizes and modular racks guarantee swift integration across diverse applications and environments.

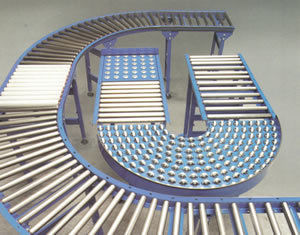

Versatile Application and Robust Usage

Our Roller Racks deliver exceptional versatility across a wide surface of application, whether used in industrial warehouses, logistic centres, supermarkets, or workshops. The modular rack system is suited for handling, storing, and sorting goods, ensuring maximum efficiency. This gravity rack type utilizes manual push rolling, ideal for facilitating both short-term and long-term storage needs in robust commercial environments. The powder-coated finishes ensure lasting durability in varied atmospheric conditions.

Sample Availability and Certifications

Roller Rack samples are available to help clients assess product quality before placing a bulk order. We maintain blue-ribbon standards with certifications for reliable domestic and export markets. Payment terms are flexibleestimate your order and benefit from smooth transactions before dispatching. Our processes are streamlined to ensure timely delivery and full satisfaction for traders, manufacturers, and suppliers across India and beyond.

Versatile Application and Robust Usage

Our Roller Racks deliver exceptional versatility across a wide surface of application, whether used in industrial warehouses, logistic centres, supermarkets, or workshops. The modular rack system is suited for handling, storing, and sorting goods, ensuring maximum efficiency. This gravity rack type utilizes manual push rolling, ideal for facilitating both short-term and long-term storage needs in robust commercial environments. The powder-coated finishes ensure lasting durability in varied atmospheric conditions.

Sample Availability and Certifications

Roller Rack samples are available to help clients assess product quality before placing a bulk order. We maintain blue-ribbon standards with certifications for reliable domestic and export markets. Payment terms are flexibleestimate your order and benefit from smooth transactions before dispatching. Our processes are streamlined to ensure timely delivery and full satisfaction for traders, manufacturers, and suppliers across India and beyond.

FAQs of Roller Rack:

Q: How do I assemble the Roller Rack and is it complex?

A: The Roller Rack offers easy boltless assembly, allowing quick installation without specialised tools. The modular design enables straightforward set-up for both novice and experienced operators.Q: What are the benefits of choosing zinc-plated steel or plastic rollers?

A: Zinc-plated steel rollers provide enhanced corrosion resistance and durability, while plastic rollers offer a lighter alternative for environments requiring less heavy-duty usage. Both ensure smooth material flow on the rack.Q: Where can the Roller Rack be effectively used?

A: This rack is suitable for applications in industrial manufacturing, warehousing, logistics centres, supermarkets, and workshops requiring organised and efficient material handling.Q: What is the process for ordering a customised Roller Rack?

A: Customers can specify their required number of layers, rack dimensions, roller material, and surface treatment. Our team provides an estimate, processes the order, and dispatches the rack once all requirements are confirmed.Q: When is a Roller Rack the preferred choice for my storage needs?

A: Opt for a Roller Rack when you need flexible, adjustable shelving capable of handling up to 50 kg per level, easy manual operation, and resistance to corrosion and harsh working conditions.Q: How does the Roller Rack contribute to efficient material handling?

A: Its gravity-based system allows quick and effortless access to stored items, reducing handling time and streamlining workflow in high-activity areas.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry