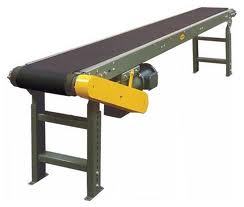

Flat Conveyors

Product Details:

- Number Of Grooves Single Groove

- Lifting Height Max 10 meters

- Bore Customizable as per requirement

- Bearing Type Heavy Duty Ball Bearing

- Mounting Type Floor Mounted

- Chain Length Custom Lengths Available

- Pulley Type Flat Belt Pulley

- Click to View more

Flat Conveyors Price And Quantity

- 1 , , Meter

- 16500 INR/Meter

Flat Conveyors Product Specifications

- Heavy Duty Ball Bearing

- Customizable as per requirement

- Max 10 meters

- Single Groove

- Floor Mounted

- Mild Steel

- Belt Sling

- Flat Belt Pulley

- Custom Lengths Available

- Electric Motor Driven

- Industrial Material Handling

- Up to 800 kg/m

- 200 mm

Product Description

We are offering our clients a broad array of Flat Conveyors. These conveyors are highly demanded in industrial sector for transporting material from one place to another. Our offered conveyors are extensively used for carrying products or items from one end to another end or place by pushing material along the floor of lodging towards the discharge. Offered conveyors are manufactured using premium grade raw materials with the help of advanced technology. We test the offered conveyors to ensure their performance prior to dispatch. Clients can avail these Flat Conveyors in various technical options at nominal prices.

Features:

- Sturdy design

- Durable finish standards

- Negligible maintenance

- Longer service life

Product details

| Material | Plastic,Stainless Steel,Rubber |

| Belt Width | 20-30 inch,30-40 inch,10-20 inch |

| Length | 20-40 feet,60-100 feet,40-60 feet |

| Capacity | 100-150 kg per feet,200-300 kg per feet,50-100 kg per feet,150-200 kg per feet |

| Structure | Belt Conveyor |

Versatile Belt Options

Flat conveyors can be equipped with PVC, rubber, or PU belts, allowing them to adapt to different material handling situations. The belt type is selected based on your applications specific requirements, including load type and environmental conditions, ensuring optimal productivity and durability.

Customizable to Fit Every Requirement

With customizable bore sizes, chain lengths, and lifting heights, these conveyors are manufactured to meet unique industrial needs. Operators can specify dimensions and capacity, ensuring seamless integration into existing processes whether used for assembly, packaging, or sorting.

FAQs of Flat Conveyors:

Q: How do flat conveyors contribute to industrial material handling efficiency?

A: Flat conveyors offer continuous and reliable movement of goods, which streamlines operations such as assembly, packaging, sorting, and warehousing. Their ability to handle loads up to 800 kg/m and speeds up to 3 m/s provides rapid transportation and distribution within industrial settings.Q: What materials are used for the conveyor belt, and how do I choose the right one?

A: The conveyor belts are made from PVC, rubber, or PU. The selection depends on the type of product being transported, exposure to chemicals, required durability, and operating environment. PVC is suitable for general applications, rubber is ideal for heavy-duty loads, and PU excels in environments requiring hygiene and flexibility.Q: When should I consider using a direct or indirect drive system for these conveyors?

A: A direct drive system is preferred when constant speed and simple operation are needed, while an indirect drive offers adjustable speed and torque for applications requiring greater flexibility. Your choice depends on the specifics of your material handling process.Q: Where are these conveyors typically installed and used?

A: Flat conveyors are floor-mounted and most commonly found in industrial settings such as manufacturing plants, warehouses, packaging facilities, and sorting centers. Their rugged mild steel construction and powder-coated finish make them suitable for demanding environments.Q: What is the process for customizing a conveyor to match my requirements?

A: Customization involves selecting appropriate belt width, material, bore size, chain length, and lifting height. Manufacturers work with users to define specifications based on load, speed, and application. This ensures the conveyor integrates smoothly into existing operations and meets specific performance needs.Q: How does using a flat conveyor benefit my operation in terms of noise and safety?

A: These flat conveyors operate at noise levels below 65 dB, creating a safer, more comfortable working environment. Their heavy-duty construction and electric motor-driven system ensure smooth, reliable, and low-maintenance performance, reducing downtime and enhancing productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry