Chain Conveyor

Product Details:

- Power Source Electric

- Thickness 5 mm Chain Plate

- Surface Finish Powder Coated

- Material Mild Steel

- Type Chain Conveyor

- Structure Mild Steel Frame

- Resistant Feature Corrosion Resistant

- Click to View more

Chain Conveyor Price And Quantity

- 40000 INR/Number

- 1 Meter

Chain Conveyor Product Specifications

- Corrosion Resistant

- 2 HP

- Electric

- 415 V

- Mild Steel

- 5 mm Chain Plate

- Chain Conveyor

- Up to 300 kg per meter

- Warehouse, Production Line, Assembly Unit, Material Handling

- Powder Coated

- Mild Steel Frame

Chain Conveyor Trade Information

- All India

Product Description

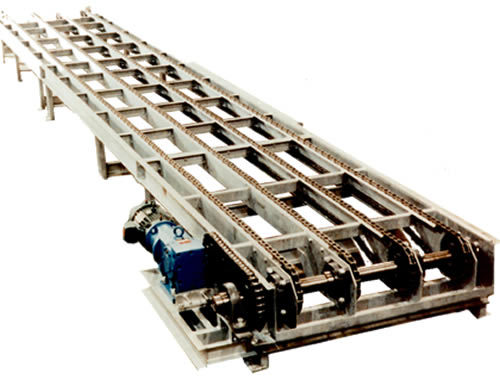

Known as a flourishing firm, we are instrumental in manufacturing, exporting and supplying optimal grade Chain Conveyor that is used for conveying the materials in convenient manner and is highly demanded in various industries like bottling, chemical, packaging, construction and many more. This conveyor is manufactured by making use of supreme grade raw materials and latest technology under the expert's supervision. Provided conveyor is also tested on various parameters to ensure its functionality at client's end. This Chain Conveyor is available in various specifications as per the application needs of clients.

- Sturdy construction

- High operational fluency

- Impeccable performance

- Negligible maintenance

Product details

| Depth | 0.03 to 0.04 |

| Brand | Star material |

| Type | Conveyor |

| Material Moving Distance | 20 to 200 feet |

| Ductility | 300 to 400 Bhn |

Optimized for Versatile Material Handling

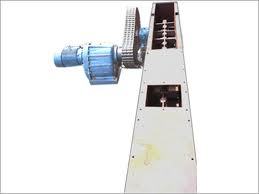

Designed for demanding industrial environments, this chain conveyor supports versatile applicationsincluding warehousing, assembly, and production. Its customizable layout accommodates varied installation spaces, optimizing workflow and productivity. The structures resilient materials ensure extended operational life and consistent performance.

Superior Build and Performance

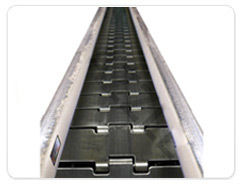

Engineered with a mild steel, powder-coated frame and 5 mm thick chain plates, this conveyor ensures durability and resistance against corrosion. The motorized system operates quietly under 70 dB, providing a safe and comfortable work environment while maintaining high load capacities.

Efficient and Reliable Operation

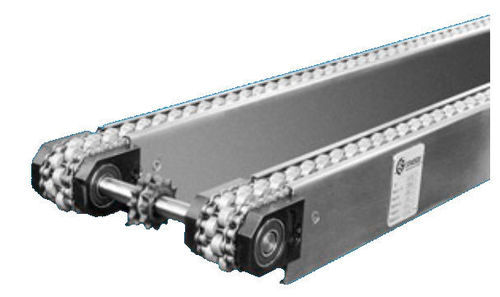

Equipped with a double pitch precision roller chain and a powerful 2 HP electric motor, this chain conveyor excels in transporting heavy goods efficiently. The carbon steel chains and mild steel frame offer robust strength, ideal for continuous industrial usage in diverse sectors.

FAQs of Chain Conveyor:

Q: How is the chain conveyor installed in various facility layouts?

A: The chain conveyor is delivered with a customizable layout, allowing for adaptations to fit unique site requirements. Its design flexibility makes it suitable for integration in warehouses, production lines, and assembly units, with on-site support provided for tailored installation.Q: What materials are used in the construction, and how do they enhance durability?

A: This conveyor is constructed with a mild steel frame and a double pitch precision roller chain made of carbon steel. The surface is powder coated, and the chain plates are 5 mm thick, providing exceptional resistance to corrosion and ensuring a long service life even under heavy loads.Q: When should I choose a double pitch, two-strand chain conveyor?

A: Opt for this model when handling large, heavy items or when extended service intervals are desired. The double pitch, two-strand design offers improved stability and load distribution, making it ideal for material handling in warehouses and industrial production lines.Q: Where can this chain conveyor be used most effectively?

A: This conveyor excels in settings such as warehouses, production lines, assembly units, and general material handling applications. It is suitable for businesses requiring efficient transportation of goods up to 300 kg per meter across varying facility layouts.Q: What is the process for powering and controlling the conveyor?

A: The conveyor operates on a 415 V electric power source, driven by a 2 HP motor. The motorized system ensures consistent and efficient movement of materials. Control options can be customized per site requirements for optimal operation and integration.Q: What are the key benefits of choosing this chain conveyor system?

A: Key benefits include a high load capacity, corrosion resistance, customizable installation, low noise operation (<70 dB), and a durable powder-coated finish. Additionally, the robust double pitch chain offers reliable performance in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry